|

Hejian Wanxiang Drilling Equipments Co., Ltd.

|

Diamond Core Bits for Oilfield

| Price: | 200.0~10000.0 USD |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

API PDC driamond core mining bit for exploration

1.Large inventory on hand

2.Good quality and after-sale service

3.Low price

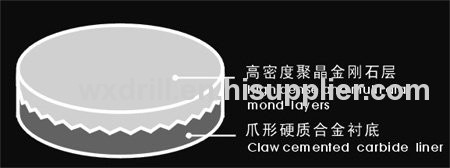

PDC Core Drill Bit

The most cost effective way to drill for a core sample.

1. B-shape crown design suitable for high abrassive and ultra hard formations.

2. Impregnated cutters with high concentration and high quaility nature diamond enhance the aggression of the bit and extend bit life.

3. Chromium-plating technology used in diamond surface, and the impact resistance and abrasion resistance highly improved .

4. Deep junk solt design brings more benefit to remove cuttings and improve ROP.

5.Can be constructed from matrix body or steel body.

6.reinforced with industrial diamonds and tungsten carbide on the inner face and outside.

7. Diamond bits and PDC bits have a much higher rate of penetration than roller con bits. Our PDC core bits will help you reduce time and cost. On average PDC diamonds are 10x harder than steel. Our bits generally have a 4-5/8" CP thread but can be tailored to any system. They can also come in standard NQ, HQ, PQ, BQ, and AQ sizes.

8. Technical Parameters:

| Size(in.) | TFA(in2) | Gauge Length(in.) | Corebarrel Size(in.) | Hydraulic Flow Rate(l/s) | Rotation Speed(rpm) | Weight on Bit(kn) |

| 6 | 0.15-1.0 | 1-1/8 | 4-3/4x2-5/8 | 6-13 | 60-200 | 36-113 |

| 8-1/2 | 0.20-1.5 | 1-1/2 | 6-3/4x4 | 11-19 | 60-200 | 68-135 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Pdc Core Bits

Diamond Pdc Bits

Diamond Router Bits

Diamond Finger Bits

Diamond Core Drill

Diamond Core Bit

More>>

.jpg)

.jpg)

.jpg)