|

Hejian Wanxiang Drilling Equipments Co., Ltd.

|

Gold Index: 59830

You are here: home > Tricone bits > Steel tooth tricone bits > API Kingdream 6" TCI Bits for Oil Field

API Kingdream 6" TCI Bits for Oil Field

| Price: | 200.0~10000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

Cover all IADC codes

Production Capacity:

30000 Piece/Pieces / Year

Delivery Date:

Within 7-10 days after the ...

Type:

Center Drill Bit

Place of Origin::

Hebei, China (Mainland)

bearing type::

Jounmal bearing

Material:

Cobalt Steel Alloy

certificate:

API,ISO

Means of Transport:

Ocean,Air

Packing:

Wooden cases or as your req...

Machine Type:

Milling Machine

Brand Name:

WX

machine type::

forging

teeth type::

insert button or milled too...

application:

oil,water well drilling

Model Number::

WX216

API 5 7/8" TCI tricone bit

1.Inserted teeth bit

2.Medium formation use

3.Metal sealed journal bearing

4.Gauge protection

API Kingdream 6" TCI Bits for Oil Well Drilling

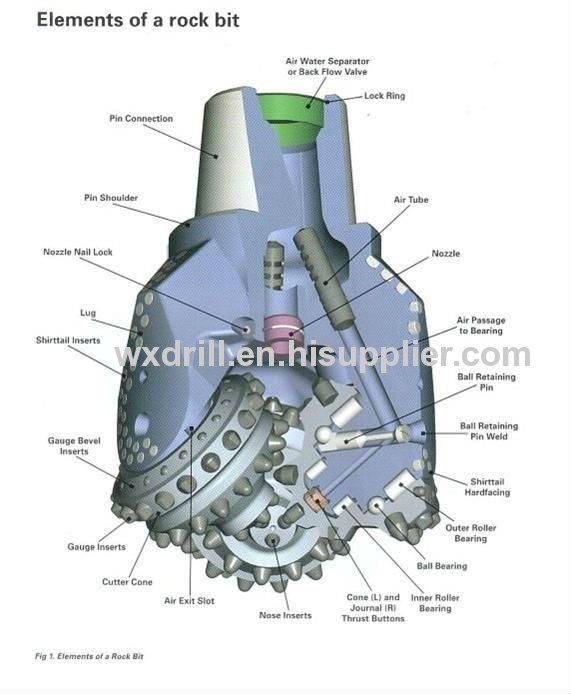

1. High precision journal bearing with two thrust faces. Head bearing surface is hard faced. Cone

bearing is inlaid with friction reducing alloy and silver-plated. The load capacity and seizure

resistance of the bearing is greatly improved.

2. Precise metal face seal. The two dynamic axial sealing rings of the sealing system are metal

seals,and two highly elastic rubber energizers are seated separately in head and cone

sealing areas functioning as static seals. Optimized sealing compression ensures good contact

between the two metal sealing faces at all times.

3. Ball locked cone, suitable for high rotary speed.

4. All-rubber compensator is used which can limit pressure differential and prevent drilling

fluid from entering the lubrication system and this provides the bearing system with good

assurance of lubrication.

5. New type of wear resistant grease that can sustain high temperature up to 250°C is utilized.

6. High wear resistance and excellent cutting ability of the insert bit are given by using carbide

compacts with high strength and high toughness in combination with optimized number of

compacts and rows,compact exposure height and special shaped compacts. For steel tooth bit,

the tooth surface is hard faced with new type of wear resistant material and thus working life

of the cutting structure is extended while high

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Hejian Wanxiang Drilling Equipments Co., Ltd. [China (Mainland)]

Business Type:Agent, Distributor/Wholesaler

City: Cangzhou

Province/State: Hebei

Country/Region: China (Mainland)

You May Like:

Product (658)

- Drill Pipes (21)

- Single Cone Bits (4)

- Hole Openers (31)

- Drag Bits (15)

- PDC Core Bits (50)

- PDC bits (135)

- Tricone bits (398)

- Others (4)

.jpg)

.jpg)

.jpg)