|

Hejian Wanxiang Drilling Equipments Co., Ltd.

|

Gold Index: 59830

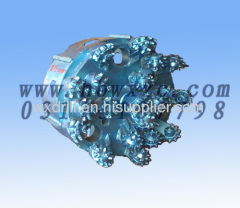

Tricone bit/ TCI tricone bit/API tricone drill bits

| Price: | 200.0~10000.0 USD |

| Payment Terms: | T/T, |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

Cover all IADC codes

Production Capacity:

30000 Piece/Pieces / Year

Delivery Date:

Within 7-10 days after the ...

Type:

Center Drill Bit

Place of Origin::

Hebei, China (Mainland)

bearing type::

sealed journal bearing

Material:

Cobalt Steel Alloys

certificate:

API,ISO

Means of Transport:

Ocean,Air,

Packing:

Wooden cases or as your req...

Machine Type:

Milling Machine

Brand Name:

WX

machine type::

forging

teeth type::

insert button or milled too...

application:

oil,water well drilling

Model Number::

WX537

1>ISO 9001:2008 & API spec7-1

2>Good quality and after-sale service.

3>30years experience in it.

1.TCI bits series:

- 1.Soft formation TCI tricone bits:

The soft formation TCI tricone bits are used to drill low compressive strength, very soft formations. This bit maximized to use of both conical and chisel tungsten carbide inserts of large diameters and high projection. This cutting structure design, combined with maximum cone offset, results in high bit penetration rates. The deep intermesh of cutter rows prevents bit bailing in sticky formations.

- 2.Medium formation TCI tricone bits:

The medium formation TCI tricone bits features aggressive chisel tungsten carbide inserts on the heel rows and inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard for mations. The HSN rubber O-ring provides adequate sealing for bearing durability.

- 3.Hard formation TCI tricone bits:

The hard formation TCI tricone bits can be used to drill hard and abrasive formations. Wear resistance tungsten carbide inserts are used in the outer rows to prevent loss of bit gauge. Maximum numbers of hemispherical shaped inserts are used in all rows to provide cutter durability and long life.

- 4.Medium hard formation TCI tricone bits:

The medium hard formation TCI tricone bits features robust chisel tungsten carbide inserts on the heel row and conical on the inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard formations. The HSN rubber O-ring provides adequate sealing for bearingdurability

2.Steel teeth bits series:

- 1.Soft formation teeth bits:

The soft formations tooth bits are used to drill low compressive strength, soft formations. Long projection tooth lengths are used on high offset cones to provide the greatest penetrations rates possible. Wear resistance hard facing is used to control tooth wear. On the softest bit types this hard facing completely covers the bit teeth.

- 2.Medium hard formations tooth bits:

The medium hard formation tooth bits are used to drill high compressive strength, medium hard formations. Shoot projection teeth with reduced crest length are used in this series of bit designs. Durable hard facing is applied to reduce tooth wear.

Model | TCI BIT, STEEL TOOTH BIT |

IADC CODE | 116 117 12 6127 136 137 216 217 226 226 316 317 326 327 336 337 115 125 135 215 225 235 315 325 335 114 124 214 314 111 121 131 346 347 |

417 427 437 517 527 537 617 627 637 737 837 832 415 425 445 525 625 635 416 427 436 446 447 516 526537 547 516 536 535 | |

Available sizes: | From 2 7/8 to 26" larger sizes for hole opener bit ,reamer bit |

Advantage | Most favourable price and best qualtity |

Bearing type: | Sealed bearing and non-sealed bearing HJ(metal sealed journal bearing) HA (rubber sealed journal bearing aircooled bearing type |

Formation orlayer | Soft ,medium soft ,hard,medium hard,very hard formation |

Button size (extra features) | Button bit,saw teeth 1) Y-Conical teeth2) X-chisel teeth 3)K- wide teeth 4)G- Gague protection |

Material | Alloy steel ,carbide |

Packing | Wooden case or steel case |

Payment terms | T/T,L/C,Western union |

Delivery terms | By sea or by air |

Delivery time | Within 3 to 7 days |

Market | Canada, USA,Middle east ,Africa,Europe |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Tci Tricone Rock Bit

Rock Tricone Bit

Tricone Rock Bits

Milled Tooth Tricone Bits

Drill Bit

Core Drill Bit

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Hejian Wanxiang Drilling Equipments Co., Ltd. [China (Mainland)]

Business Type:Agent, Distributor/Wholesaler

City: Cangzhou

Province/State: Hebei

Country/Region: China (Mainland)

You May Like:

Product (658)

- Drill Pipes (21)

- Single Cone Bits (4)

- Hole Openers (31)

- Drag Bits (15)

- PDC Core Bits (50)

- PDC bits (135)

- Tricone bits (398)

- Others (4)

.jpg)

.jpg)

.jpg)