|

Hejian Wanxiang Drilling Equipments Co., Ltd.

|

Gold Index: 59830

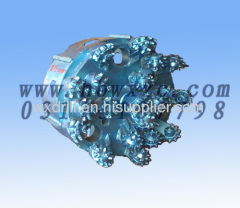

IADC627 stone drilling tools

| Price: | 1000.0~8000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

IADC627

Packing:

Wooden cases or as per cust...

Application:

Coal

Brand Name:

Wanxiang

Processing Type:

Forging

Certification:

API

WOB(kN/mm):

0.35~1.05

Bearing:

Journal Bearing

Production Capacity:

20000 Piece/Pieces per Year

Delivery Date:

Within 7-10 days after rec...

Type:

Drill Bit

Place of Origin:

Hebei, China (Mainland)

Material:

Tungsten Carbide

RPM(r/min):

110~40

Sealing Type:

Milled Sealing

Tooth Type:

Insert Tooth Bit

IADC627 stone drilling tools

1.Fast drilling rate

2.Strong cutting structure durability

3.Diffrernt size available

4.Low cost

IADC627 coal mining rock bit stone drilling tools

Tricone bit

1.High-strength, high flexibility, high temperature, high wear resistance.

2. High-precision metal seal.

3. Locking roller ball, to adapt to high-speed.

4. The use of high strength high toughness carbide teeth,

5. Hours in the rotary cone bit with the impact, crushing and shearing the role of broken rock.

6. Cone bit to adapt to the soft, medium and hard of various strata.

7. Reasonable price and long working life.

1.High-strength, high flexibility, high temperature, high wear resistance.

2. High-precision metal seal.

3. Locking roller ball, to adapt to high-speed.

4. The use of high strength high toughness carbide teeth,

5. Hours in the rotary cone bit with the impact, crushing and shearing the role of broken rock.

6. Cone bit to adapt to the soft, medium and hard of various strata.

7. Reasonable price and long working life.

Structural features:

1.Cutting structure this type TCI tricone bits:

The durability of premium tungsten carbide insert is improved with new formulas and new techniques

for insert bit.

2.Gauge structure this type TCI tricone bits:

Multiple gaugeprotection with gauge trimmers on the heel of cone,

tungsten carbide inserts and hardfacing on the shirttail increases gauge holding capability and bearing life.

3.Bearing structure of this type TCI tricone bits:

High precision bearing with two thrust faces. Ball lock the cone.

Hardfaced head bearing surface. Cone bearing inlaid with friction-reducing alloy and then silverplated.

Abrasion resistance and seizure resistance of the bearing are improved.

4.Seal and Lubrication of this type TCI tricone bits:

Premium O-ring, optimal seal compression and curved seal structure can enhance the seal performance.

The pressure compensator system and advanced grease can greatly increase the lubricating reliability .

5.Product Application this type TCI tricone bits:

It can receive high WOB in the conventional drilling.

It is suitable for various formations by matching cutting structure with different tooth shape,

tooth density and tooth exposure height.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Drilling Tools

Dth Drilling Tools

Drilling Electric Tools

Electric Drilling Tools

Foundation Drilling Tools

Tapered Rock Drilling Tools

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Hejian Wanxiang Drilling Equipments Co., Ltd. [China (Mainland)]

Business Type:Agent, Distributor/Wholesaler

City: Cangzhou

Province/State: Hebei

Country/Region: China (Mainland)

You May Like:

Product (658)

- Drill Pipes (21)

- Single Cone Bits (4)

- Hole Openers (31)

- Drag Bits (15)

- PDC Core Bits (50)

- PDC bits (135)

- Tricone bits (398)

- Others (4)