|

Hejian Wanxiang Drilling Equipments Co., Ltd.

|

Gold Index: 59830

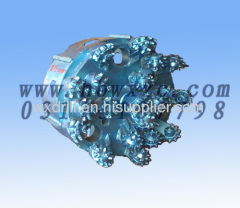

IADC547 underground drilling machine

| Price: | 1000.0~8000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

IADC547

Packing:

Wooden cases or as per cust...

Application:

Ore

Brand Name:

Wanxiang

Processing Type:

Forging

Certification:

API

WOB(kN/mm):

0.35~1.05

Bearing:

Journal Bearing

Production Capacity:

20000 Piece/Pieces per Year

Delivery Date:

Within 7-10 days after rec...

Type:

Drill Bit

Place of Origin:

Hebei, China (Mainland)

Material:

Tungsten Carbide

RPM(r/min):

110~40

Sealing Type:

Milled Sealing

Tooth Type:

Insert Tooth Bit

IADC547 underground drilling machine

1.Fast drilling rate

2.Strong cutting structure durability

3.Diffrernt size available

4.Low cost

IADC547 journal bearing tricone drill bit for water well drilling

TCIbits series:

Soft formation TCI tricone bits:

The softformation TCI tricone bits are used to drill low compressive strength, very softformations. This bit maximized to use of both conical and chisel tungstencarbide inserts of large diameters and high projection. This cutting structuredesign, combined with maximum cone offset, results in high bit penetrationrates. The deep intermesh of cutter rows prevents bit bailing in stickyformations.

Mediumformation TCI tricone bits:

The medium formation TCI triconebits features aggressive chisel tungsten carbide inserts on the heel rows andinner rows. This design provides a fast drilling rate and added cuttingstructure durability in medium to medium hard for mations. The HSN rubber O-ringprovides adequate sealing for bearing durability.

Hard formation TCI tricone bits:

The hard formation TCI tricone bits can be used to drill hardand abrasive formations. Wear resistance tungsten carbide inserts are used inthe outer rows to prevent loss of bit gauge. Maximum numbers of hemisphericalshaped inserts are used in all rows to provide cutter durability and long life.

Medium hard formationTCI tricone bits:

The medium hard formation TCI tricone bitsfeatures robust chisel tungsten carbide inserts on the heel row and conical onthe inner rows. This design provides a fast drilling rate and added cuttingstructure durability in medium to medium hard formations. The HSN rubber O-ringprovides adequate sealing for bearing durability.

Soft formation TCI tricone bits:

The softformation TCI tricone bits are used to drill low compressive strength, very softformations. This bit maximized to use of both conical and chisel tungstencarbide inserts of large diameters and high projection. This cutting structuredesign, combined with maximum cone offset, results in high bit penetrationrates. The deep intermesh of cutter rows prevents bit bailing in stickyformations.

Mediumformation TCI tricone bits:

The medium formation TCI triconebits features aggressive chisel tungsten carbide inserts on the heel rows andinner rows. This design provides a fast drilling rate and added cuttingstructure durability in medium to medium hard for mations. The HSN rubber O-ringprovides adequate sealing for bearing durability.

Hard formation TCI tricone bits:

The hard formation TCI tricone bits can be used to drill hardand abrasive formations. Wear resistance tungsten carbide inserts are used inthe outer rows to prevent loss of bit gauge. Maximum numbers of hemisphericalshaped inserts are used in all rows to provide cutter durability and long life.

Medium hard formationTCI tricone bits:

The medium hard formation TCI tricone bitsfeatures robust chisel tungsten carbide inserts on the heel row and conical onthe inner rows. This design provides a fast drilling rate and added cuttingstructure durability in medium to medium hard formations. The HSN rubber O-ringprovides adequate sealing for bearing durability.

Technical Parameters:

No | IADC Code | Recommendation | |

WOB(KN/mm) | Rotary Speed(rpm) | ||

1 | 117 | 0.35~0.8 | 240~80 |

2 | 127 | 0.35~0.9 | 240~70 |

3 | 437 447 | 0.35~0.9 | 240~70 |

4 | 517 527 | 0.35~1.0 | 220~60 |

5 | 537 547 | 0.45~1.0 | 220~50 |

6 | 617 627 | 0.45~1.1 | 200~50 |

7 | 637 | 0.5~1.1 | 180~40 |

We welcome specific requests to meet your needs!

Please contact us for more information!

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Drilling Machine

Drilling Machine Cnc

Drilling And Milling Machine

Cnc Drilling Machine

Drilling Milling Machine

Bench Drilling Machine

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Hejian Wanxiang Drilling Equipments Co., Ltd. [China (Mainland)]

Business Type:Agent, Distributor/Wholesaler

City: Cangzhou

Province/State: Hebei

Country/Region: China (Mainland)

You May Like:

Product (658)

- Drill Pipes (21)

- Single Cone Bits (4)

- Hole Openers (31)

- Drag Bits (15)

- PDC Core Bits (50)

- PDC bits (135)

- Tricone bits (398)

- Others (4)